Solutions For Vapour Phase

Solutions For Vapour Phase

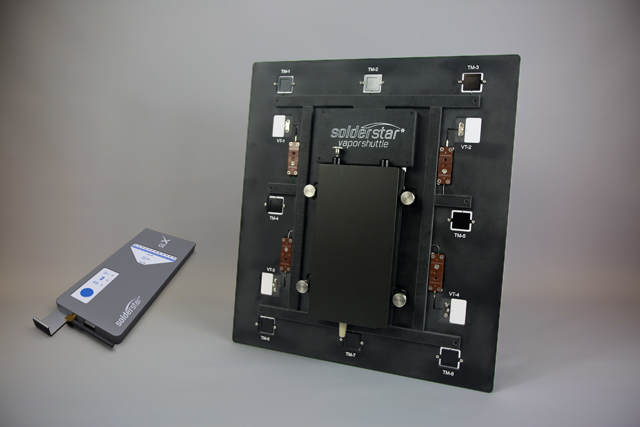

The VaporShuttle Uniformity Fixture is designed to enable precise machine-level qualification and routine verification of vapour phase soldering systems, focusing on the performance of the reflow chamber itself rather than the characteristics of individual PCBs.

The fixture incorporates a standardised thermal test plate equipped with thermocouples positioned at strategic locations.

This configuration allows for the generation of a comprehensive thermal uniformity profile, characterising the machine’s heat distribution across the active process area. This dedicated verification tool is essential for a range of process control tasks, including:

Paired with the VP10 Thermal Profiler, VaporShuttle clearly distinguishes machine-related variations from PCB thermal characteristics. This combined approach confirms uniform heat distribution, verifies proper soldering conditions, and quickly identifies whether issues stem from equipment or design — helping manufacturers optimise process parameters, meet audit requirements, and ensure repeatable, high-reliability results.